Have any questions?

+44 1234 567 890

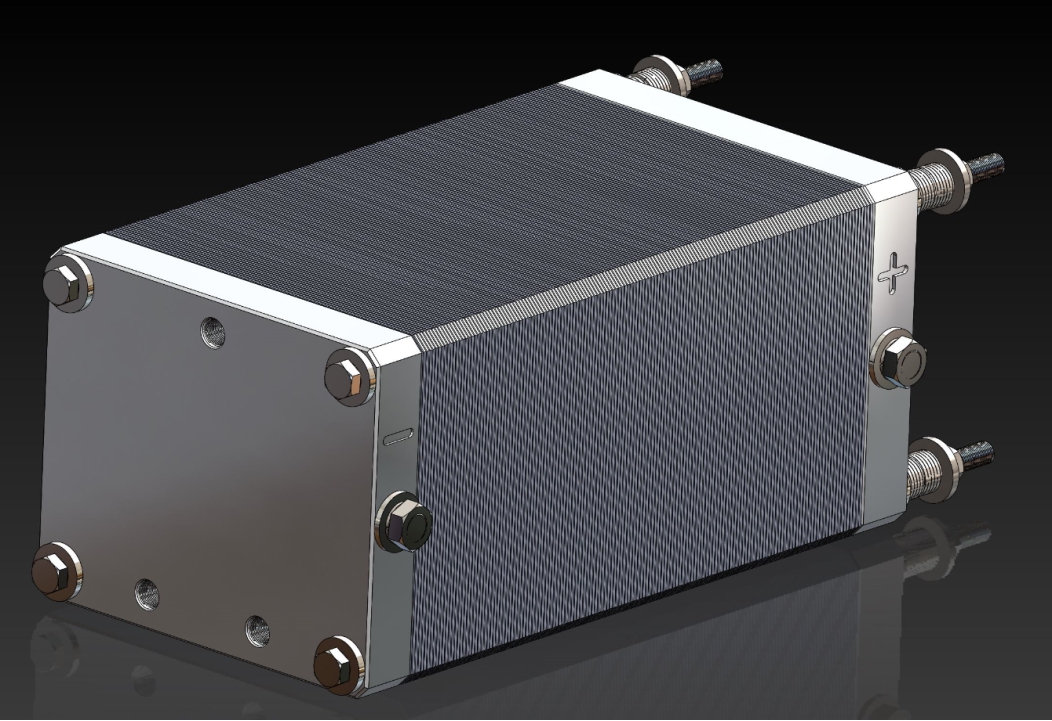

Electrolysis

Chemical energy conversion - competence for electrolysis

In the context of the energy transition, technologies that can temporarily store fluctuating energy production generated by renewable energies (wind, solar) play a decisive role. Climate-neutral, green hydrogen produced by electrolysis is considered to be the energy source of the future and represents a key technology in the area of the power-to-gas concept. For the success of the energy transition, alternative CO2-free components are required as energy carriers.

Hydrogen can be stored and is used e.g. in the chemical industry or in the transport and energy sectors. The production of hydrogen by water electrolysis is based on the electrochemical splitting of water in an electrolyser into hydrogen and oxygen by using electrical energy. The challenge is to reduce the production costs and to increase the efficiency. OM develops new electrode and catalyst materials to improve the overall performance and to bring down the costs and, hence, to close the gap between research and application. The approach is to significantly reduce energy losses at the electrode (reduction of overpotentials) and to increase the overall performance by an optimized "bubble management" to achieve an increase in current densities. OM relies on the development of advanced cell designs, new electrode materials and catalyst layers with high long-term stability.

Areas of work:

Development of advanced cell designs for electrolysis:

- Catalyst and electrode materials

- Porous transport layers (PTLs)

- Bipolar plate/PTL units

Characterization of materials and components in the electrolysis test cell:

- Development of standardized, electrochemical test protocols for catalyst materials obtaining comparable results

- Evaluation of new components by material screening

- Aging tests of cell components

- Structural analysis