Have any questions?

+44 1234 567 890

Substrate

Metal substrate

The core competence of Oberland Mangold: soldered metal carriers.

Oberland Mangold has been producing metal substrates which are used as catalytic converters or filter substrates in a variety of applications for more than 25 years. The applications range from small engines to motorcycles, passenger cars, utility vehicles and construction machines to block heat and power plants and industrial plants.

The low cell wall thickness allows for a smaller overall size of installation with a low net weight of the substrate: this is a crucial advantage. The metal materials are temperature-stable up to 1200°C. In addition, they offer optimal thermal conductivity and high mechanical strength. This makes integration into the respective exhaust system possible near to the engine. Since the metal substrate is welded directly into the exhaust system, the time required to install the system is reduced considerably when compared to ceramic solutions.

structures

Catalytic converter structures

Structure

The cell matrix of the metal substrates from Oberland Mangold consists of paper-thin, high-alloy stainless steel sheets. This metal composite is brazed in a high vacuum and offers an outstanding performance potential.

The advantages of this structure are clear:

- Small cell wall thicknesses and therefore a favourable ratio of open cross-section flow to the geometric surface area.

- Very good thermal and mechanical stability guarantees a broad range of application.

- High resistance to temperature shocks. This results in long service lives.

- Can be welded directly as it has no additional components. This means an easy integration into the respective exhaust system.

- Full metal structure offers the best recycling properties

In addition to the uncoated metal substrates, you can also receive a fully coated catalytic converter whose coating is custom-made to fit your needs.

Areas of application

The metal carriers as catalytic converter substrates are used everywhere there are high demands on the thermomechanical properties of the catalytic converter. High catalytic turnover rates with a simultaneously limited installation space and low exhaust gas back pressures are the outstanding features.

- Small engines with a carrier diameter from 20 mm.

- Motorcycles

- Passenger cars

- Utility vehicles

- Industrial facilities with a carrier diameter of up to 1200 mm

structures

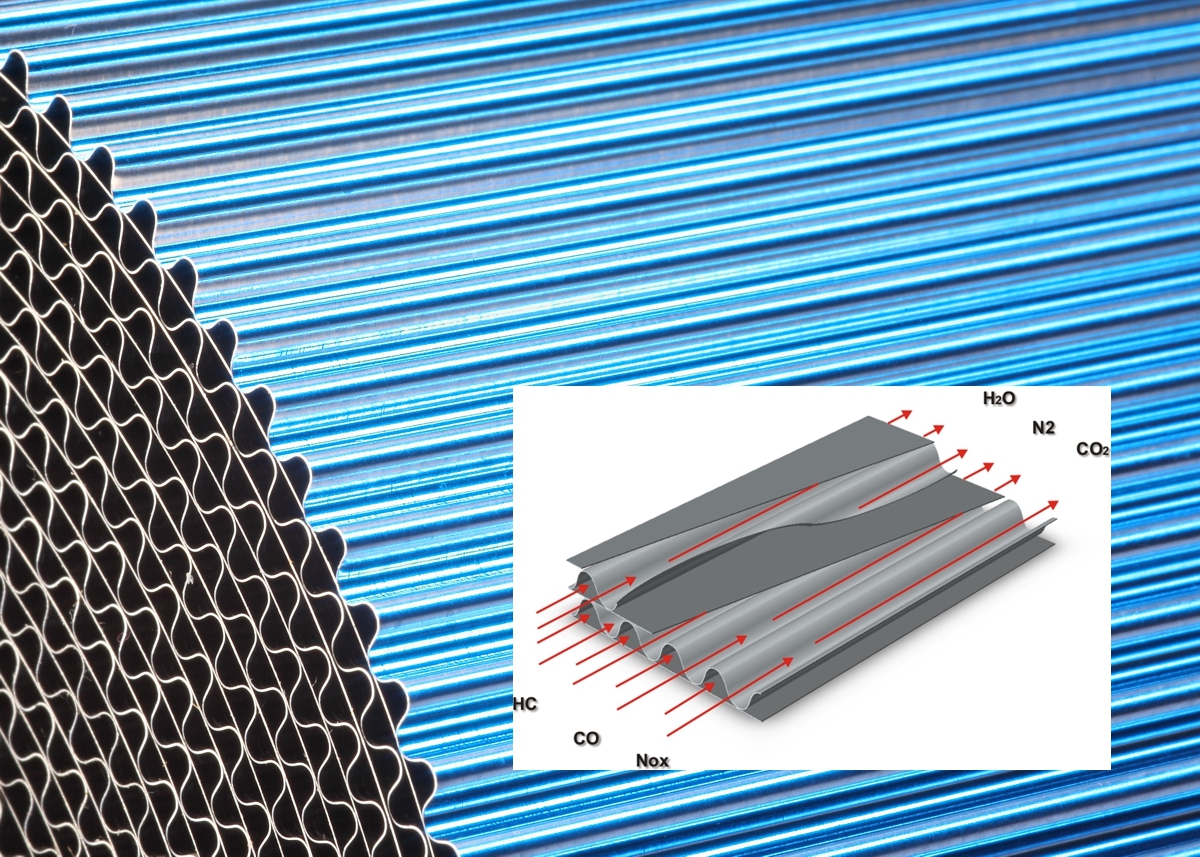

Standard cell structure

Use as DOC or 3-way catalytic converter

- Low exhaust back-pressure level

- Large range of cell densities available

- A variety of different lengths

- High thermo-mechanical resistance

- Low canning expense

WF

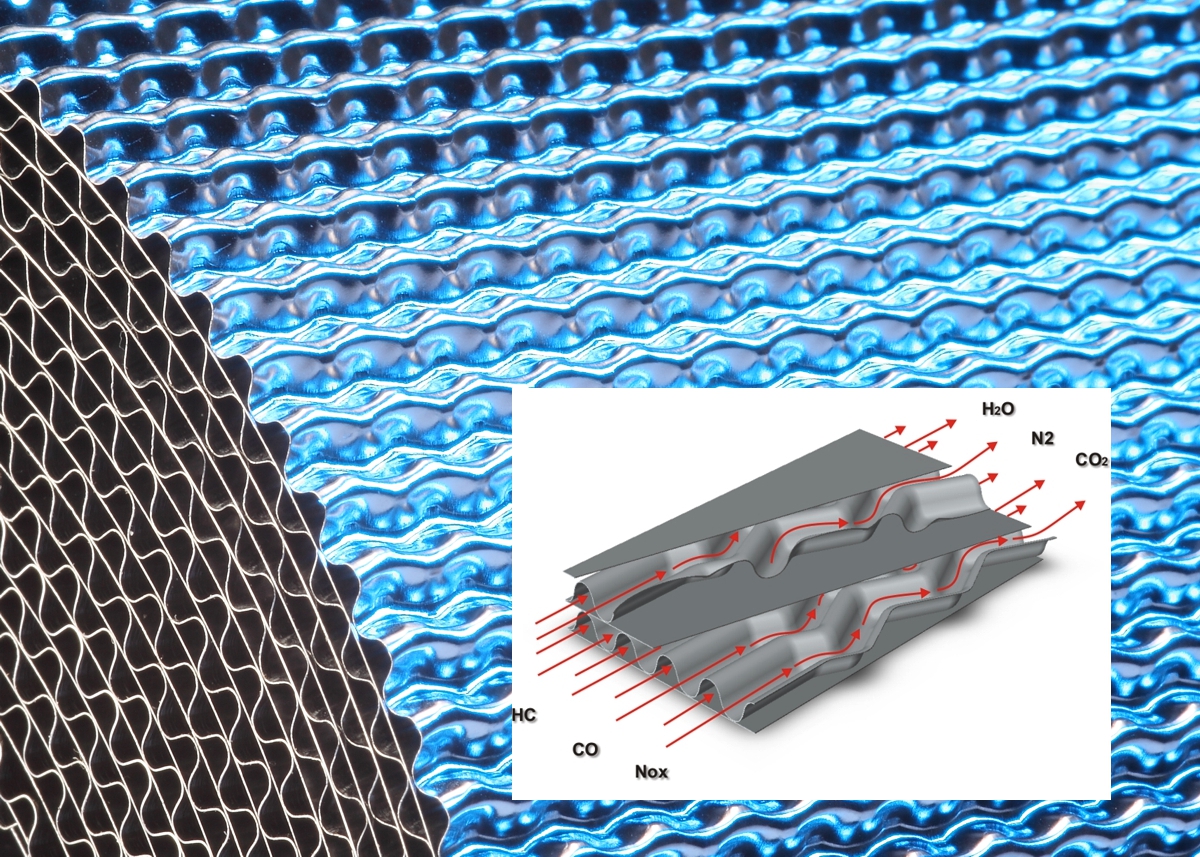

WF (wave flow) cell structure

Use as DOC or 3-way catalytic converter with a greater degree of efficiency

- Improved gas exchange via the channel cross-section

- Increased catalytic activity

- Improved light-off behaviour

- High thermo-mechanical resistance

- Low canning expense

open

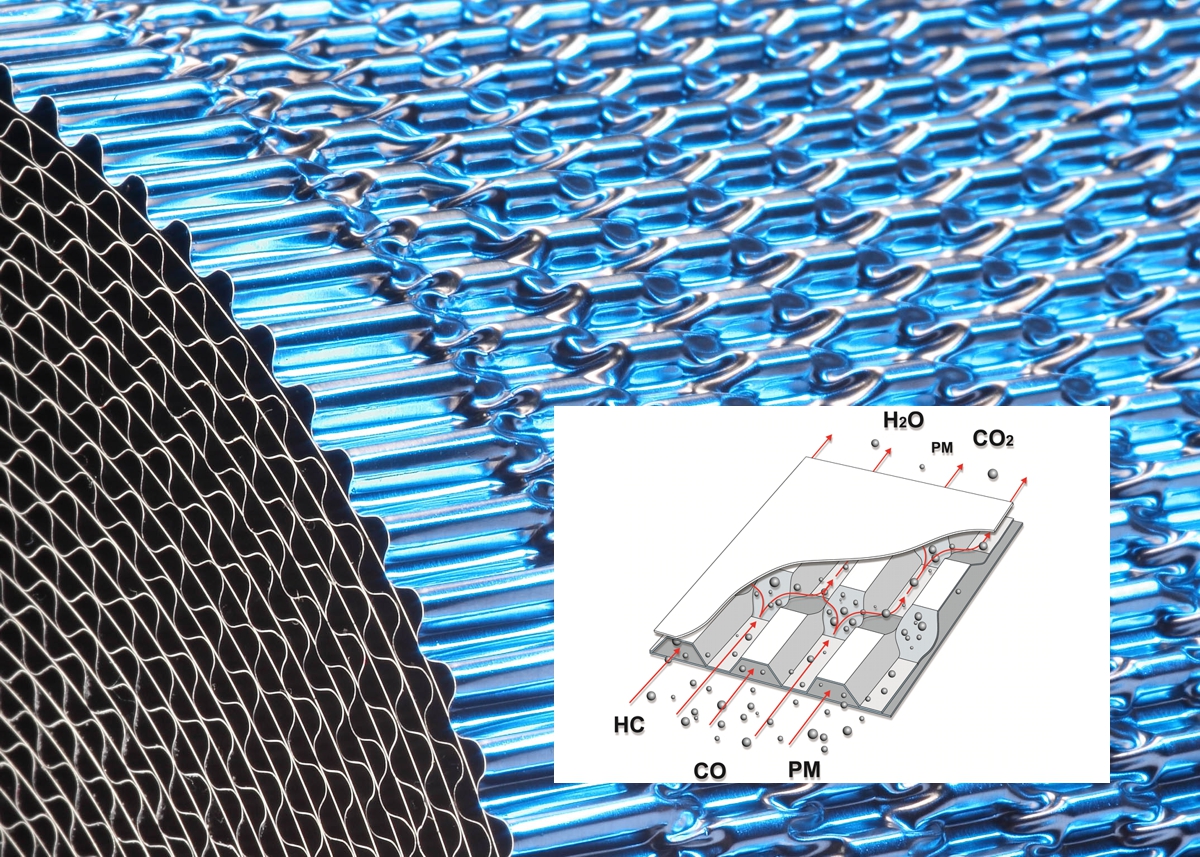

Open filter structure

Application of a passive particulate reduction system

- Effective reduction of particulate emissions (30 – 50 %)

- No active regeneration required

- No risk of blocking the structure with soot

- Catalytically coatable

- Less canning expense